Extremely nutritional corn oil also known as maize oil is extracted from the germ of the corn. It is commonly used as cooking oil but its high smoke point makes it highly valued frying oil. Apart from cooking, refined corn oil is also used in the preparation of margarine.

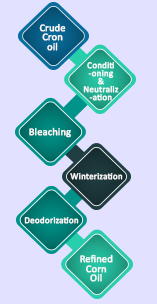

Process of Refining Corn Oil

Crude Corn oil is refined through alkali neutralization process which is a chemical refining process and involves numerous steps. The major steps involved in refining of crude corn oil through alkali neutralization are –

- Gums conditioning Neutralization

- Bleaching

- Winterization

- Deodorization

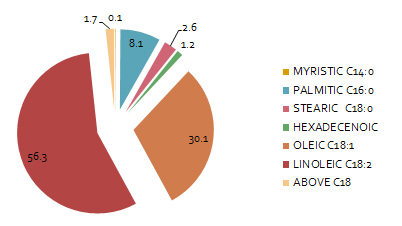

Fatty ACID Composition

Gums conditioning & Neutralization

In this process, the crude oil is first treated with acid (citric acid/ phosphoric acid) followed by treatment with alkali to neutralize the oil which is followed by soap separation. Further the soap separated oil is washed from hot water for removing the traces of soap, later dried for obtaining neutralized oil.

This process further involves four steps listed below –

- Conditioning – in this step, non-hydratable phospholipids are transformed into their hydratable form by breaking down the phosphatide/metal complexes by using a strong acid.

- Neutralization – free fatty acids are neutralized by an alkali for creating the sodium salt of free fatty acids

- Washing – in this step, residual soap is removed by washing it from the hot water.

- Drying – in this step, the leftover moisture is removed from the oil under vacuum.

Bleaching

In this process, the higher melting point parts such as saturated triglycerides and waxes are removed from the oil. The vegetable oil is slowly cooled and saturated glycerides are crystallized. This process consists of fractional crystallization of fats and oil which is further followed by solid-liquid separation through filter.

Winterization

In this process, the higher melting point parts such as saturated triglycerides and waxes are removed from the oil. The vegetable oil is slowly cooled and saturated glycerides are crystallized. This process consists of fractional crystallization of fats and oil which is further followed by solid-liquid separation through filter.

De-Acidification Cum Deodorization

This is the last step of edible oil refining in which a certain amount of stripping agent is passed through hot oil for a certain period of time at quite a low pressure. The pre-treated oil is further processed for removing fatty acids, odour and other constituents.

This process is carried out at high temperature as well as under high vacuum along with sparging steam. This process removes the remaining free fatty acids and odoriferous compounds making the oil fit for human consumption. This process generally has two effects on oil –